TL;DR

Great DTF prints start with great film. The film you choose affects color vibrancy, edge sharpness, peel smoothness, and even production efficiency.

Learn how to spot a quality DTF film—and how the wrong one can quietly kill your profit margin.

1️⃣ What Makes DTF Film So Important?

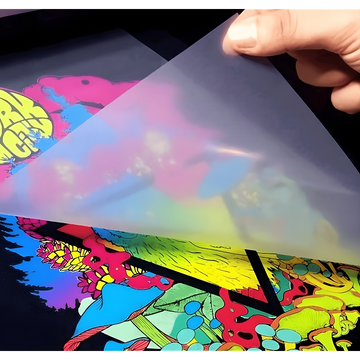

DTF (Direct-to-Film) printing transfers ink from a coated PET film onto fabric using heat and adhesive powder.

That means your film is literally the foundation of every print.

A good DTF film ensures:

-

Ink stays sharp — no bleeding or spreading.

-

Powder coats evenly — smooth surface, even bonding.

-

Clean peel — no edge tearing or ghosting.

-

Consistent release — predictable transfers every time.

Cheap or unstable film causes:

❌ Fuzzy edges

❌ Ink migration

❌ Static dust spots

❌ Peeling issues after washing

2️⃣ 3 Main Types of DTF Film (and When to Use Them)

| Type | Peel Timing | Best For | Key Benefit |

|---|---|---|---|

| Hot Peel Film | Peel right after pressing | High-speed production | Fastest workflow |

| Warm Peel Film | Peel when film is warm (not hot) | General-purpose jobs | Balance of quality & speed |

| Cold Peel Film | Peel after cooling | Small text, detailed art | Cleanest edges, most forgiving |

Pro Tip:

If your team handles large daily volumes, go with hot peel for faster turnaround.

If you’re doing fine logos or detailed artwork, use cold peel for cleaner results.

3️⃣ Film Surface: Why Double-Matte Anti-Static Is a Game-Changer

Double-matte anti-static films are the industry gold standard.

✅ Smoother feeding in roll printers

✅ Anti-dust, no static buildup

✅ Cleaner powder spread

✅ Easier stacking, no sticking

✅ Better consistency for long runs

If you’re scaling up production or running automated powder shakers, this feature saves hours of downtime.

4️⃣ 75μm vs 100μm: Which Thickness Fits You?

| Thickness | Pros | Best For |

|---|---|---|

| 75μm | More flexible, lower cost | Small shops, mixed fabrics |

| 100μm | Flatter, stable feeding | Large runs, wide printers |

👉 Rule of thumb:

Go 75μm if you print many garment types in small batches.

Go 100μm if you focus on long runs and need perfect registration.

5️⃣ Quick Testing Checklist Before Full Production

-

Print a 10×10 cm test image.

-

Apply powder and cure.

-

Press and peel as normal.

-

Check:

-

Edge clarity

-

White coverage

-

Peel smoothness

-

Wash test (40°C, 5 cycles)

-

If edges lift or colors fade — your film or curing settings may need adjustment.

6️⃣ Top 5 Film Mistakes to Avoid

-

Using glossy films → static issues, dust spots

-

Skipping humidity control → curled films

-

Using wrong peel type → tearing or ghosting

-

Skipping post-press step → poor wash durability

-

Mixing film and powder brands → inconsistent adhesion

🏆 Final Takeaway

DTF film is not just a carrier — it’s a critical performance component.

Choose the right type (hot, warm, or cold peel), the right coating (double-matte), and the right thickness (75µm or 100µm), and you’ll get sharper prints, faster peels, and happier customers.

💪 Why Choose KungFuDTF?

At KungFuDTF, we manufacture and supply:

-

🧩 Hot, warm, and cold peel films

-

⚡ Double-matte anti-static coatings

-

🎯 75μm & 100μm thickness options

-

🧪 Tested with KungFu inks and TPU powder for perfect adhesion

Get consistent quality from a factory-direct source — and boost your print shop’s efficiency today.