TL;DR

What it does: Bonds ink to fabric—your durability lives or dies here.

Choose right: Fine for detail/soft hand, Medium for all-round, Coarse for heavy fabrics.

Nail the process: Even powder → proper curing → firm press → quick post-press.

Win on quality: Clean edges, bright color, high wash-resistance

🎯 Who Is This For?

Print shops, apparel brands, and merch teams that want fewer rejects, faster throughput, and happier customers—without guessing at settings.

1) What Is DTF Hot-Melt Powder (TPU)?

In DTF (Direct-to-Film) printing, hot-melt powder sits on your printed ink, gets cured to fuse with it, and then—under the heat press—flows into fabric fibers to create a tough, flexible bond. The result? Vivid color, clean edges, and wash durability your customers notice.

2) Pick the Right Particle Size (Fast Reference)

| Particle | Typical Use Cases | Hand Feel | Detail | Bond Strength | Why Choose It |

|---|---|---|---|---|---|

| Fine | Tees, infantwear, delicate knits | Softest | ★★★★☆ | ★★★☆☆ | Best for crisp edges & micro-details |

| Medium | Everyday cotton/poly blends | Balanced | ★★★☆☆ | ★★★★☆ | Your reliable “one-powder-fits-most” |

| Coarse | Hoodies, canvas, heavy textiles | Fuller | ★★☆☆☆ | ★★★★★ | Extra grab on bulky/rough surfaces |

Pro tip: If your artwork is thin lines or micro text, Fine improves edge cleanliness. For bulk hoodies/totes, Coarse locks in.

3) Your Process Cheat Sheet (Save This)

A) Curing the Powder (after printing)

-

Temperature (on powder layer): 110–130 °C

-

Time: 2–5 min (until powder turns evenly translucent, not sandy)

-

Goal: Smooth, fully fused powder film that won’t smudge to the touch

B) Heat Press Transfer

-

Cotton / Blends: 155–165 °C, 10–15 s, medium-firm pressure

-

Poly / Stretch: 150–160 °C, 12–20 s, medium pressure

-

Peel: Follow your film type (hot/ warm/ cold)

-

Post-press: 5–10 s with a protective sheet to boost wash-resistance & surface flatness

4) Fix Problems Fast (Troubleshooting Matrix)

| Symptom | Likely Cause | Quick Fix |

|---|---|---|

| Rough, sandy surface | Under-cured powder / particles too large | Raise cure temp/time, switch to finer powder |

| Lifting corners / peeling | Under-cured or under-pressed | Increase cure completeness; add pressure/time; always post-press |

| Fuzzy edges / “halo” | Over-powdering or static | Reduce powder; improve grounding; use anti-static film |

| Cracking after washes | Brittle bond / no post-press | Use more elastic TPU powder; add post-press 5–10 s |

| Yellowing of whites | Over-cured (too hot/too long) | Lower cure temp/time; improve airflow/temperature uniformity |

| Dye migration on poly | Heat too high for substrate | Use lower-temp, longer press; use migration-barrier sheet |

5) Cost & Consumption (Simple Math)

-

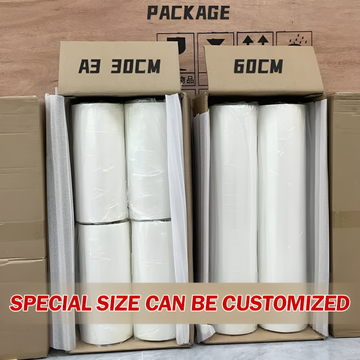

Typical powder per A3: 10–25 g (art coverage & particle size affect this)

-

Estimate formula:

Powder (kg) = Number of sheets × grams per sheet ÷ 1000 -

Example: 500 × A3 at 15 g → 7.5 kg powder

-

Save more: Tighten artwork coverage, recycle excess powder, optimize curing so you can run thinner powder layers reliably.

6) Storage & Environment (Quality = Consistency)

-

Humidity: 45–55% RH (too wet → clumping; too dry → static & uneven powder)

-

Keep sealed, cool, and dark; consume opened bags within 3–6 months

-

Use FIFO (first-in-first-out) and log batch + settings for traceability

7) Quality Control Checklist (Before You Ship)

-

Wash tests: 40 °C, 5–10 cycles → no peeling, no obvious fading

-

Adhesion: Tape/score tests show firm edge integrity

-

Stretch: No cracking on athletic/stretch fabrics

-

Rub fastness: 200–500 rubs (dry/wet) without visible powder loss

8) Ready-Made Recipes (Copy/Paste to Start)

-

Soft Fashion Tee: Fine powder • Cure 115–120 °C / 3–4 min • Press 160 °C / 12 s • Post-press 8 s

-

All-Round Daily Orders: Medium powder • Cure 120–125 °C / 3–4 min • Press 160 °C / 12–15 s • Post-press 6–8 s

-

Heavy Hoodie/Canvas: Coarse powder • Cure 125–130 °C / 4–5 min • Press 165 °C / 15–18 s • Post-press 10 s

Always run a 2–3 sheet test when you change powder, film, ink, or garment.

✅ Takeaway

If you want fewer rejects and happier customers, treat hot-melt powder like your secret weapon: choose the right particle size, cure it properly, press it firmly, and always post-press. Do that, and your prints look better, feel softer, and survive more washes.

Why KungFuDTF?

We supply fine / medium / coarse TPU powders vetted on cotton, poly, blends, hoodies, canvas, and stretchwear—with clear data sheets, batch consistency, and fast dispatch. Need help dialing in your settings? Our team can benchmark your film-ink-powder combo and hand you a working recipe.

👉 Get samples or a bulk quote today.